Rigid portal frames in mezzanine floors

In modern production and logistics environments every square metre is valuable. Mezzanine floors provide extra floor area without expanding the building. Yet companies often face a limitation: bracing. While bracing adds stability to traditional steel structures, in practice it creates obstacles that block walking routes and forklift movements. The solution? Rigid portal frames.

Why traditional bracing often causes problems

Bracing consists of diagonal supports that keep a steel structure stable. They cross the open space under the floor and strengthen the construction. The downside is that they block the very same open space. For companies with intensive logistics processes this means less flexibility in placing racks or machines and limitations for internal transport. The free layout of a warehouse or production line is therefore under pressure.

What are rigid portal frames?

A rigid portal frame consists of columns and beams that are rigidly connected. These connections absorb bending moments, allowing the structure to withstand horizontal forces such as wind loads independently. For mezzanine floors this means that stability is built into the frame without the need for bracing. The result is an open space under the floor that can be fully used for transport, storage or production.

The benefits of rigid portal frames for mezzanine floors

Free space under the floor: without bracing the space remains fully accessible for forklifts, AGVs or conveyors.

Flexible layout: the open structure makes it easy to reposition racks, machines or production lines.

Higher efficiency: without obstacles logistics processes run faster and the risk of damage from collisions decreases.

Clarity and overview: the open structure provides better visibility, more daylight and a clear work floor.

Fast assembly and disassembly: rigid portal frames can be prefabricated, speeding up installation. They are also easier to dismantle or relocate, which is attractive for circular applications.

Comparison: bracing versus rigid portal frames

| Feature | Bracing | Rigid portal frames |

|---|---|---|

| Space use | Limited by diagonal supports | Completely free, no obstacles |

| Flexibility | Less flexible, fixed zones | Highly flexible, freely adaptable |

| Efficiency | Obstacles for transport and routing | Faster processes, lower risk of damage |

| Assembly | Relatively simple but permanent | Fast, demountable and reusable |

| Cost | Lower initially, but limited usability | Higher investment, but maximum use |

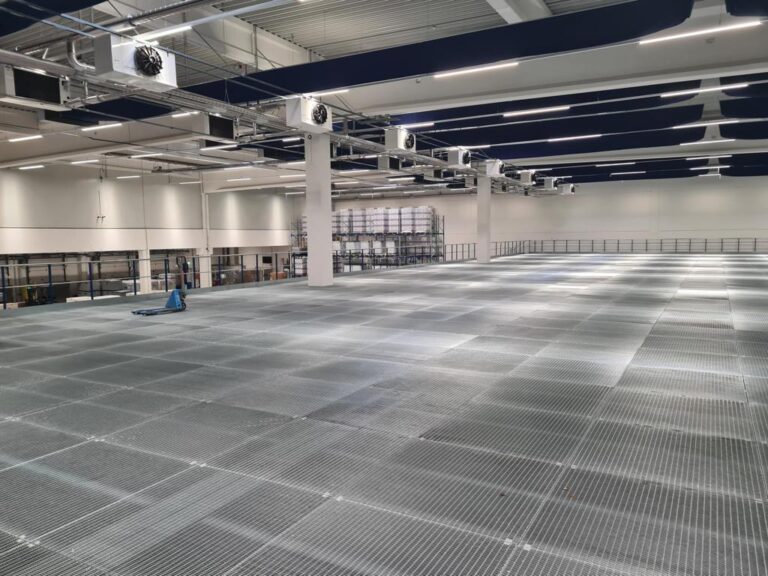

Case study: mezzanine without compromises

In a recent project for logistics service provider Bleckmann in Almelo a mezzanine floor of 33,000 m² was built using a fully rigid portal frame structure. As no bracing was required, the space under the floor could be fully used for picking locations, a conveyor belt and free passage for internal transport. The result: maximum functional space with minimal limitations.

A future-proof choice for industry and logistics

Rigid portal frames perfectly match the needs of modern companies. They make optimal use of available space, increase flexibility and contribute to circular construction methods as they can be dismantled. Whether for a new mezzanine in a warehouse, an extension of a production line or a temporary floor in a factory, rigid portal frames prove their value time and again. They offer an investment that pays back in convenience and efficiency.

Recent opgeleverde projecten

Door de jaren heen hebben we met Nolte Mezzanine al vele mooie projecten op mogen leveren. We spreken over verschillende groottes, verschillende type vloeren en daardoor heel verschillende resultaten. Oftewel: we weten precies wat er allemaal mogelijk is. Bekijk onze projecten en ontdek het zelf!

Frequently asked questions about rigid portal frames

What is the difference between rigid portal frames and bracing?

Bracing adds stability but blocks space. Rigid portal frames integrate stability into the frame, keeping the space completely open.

When should you choose rigid portal frames?

Rigid portal frames are especially useful in environments where forklifts, AGVs or conveyors are used, or when flexibility and open layouts are important.

Are rigid portal frames more expensive than traditional structures?

The investment is higher, but because the space can be fully used and processes run more efficiently, they deliver a higher return in the long term.

Can rigid portal frames be reused?

Yes, the structures can be dismantled and rebuilt. This makes them suitable for circular applications and temporary projects.